slide 2 of 8

Electrochemical

Additive

Manufacturing

Mass Production of Next

Generation Components

Mass Production of Next

Generation Components

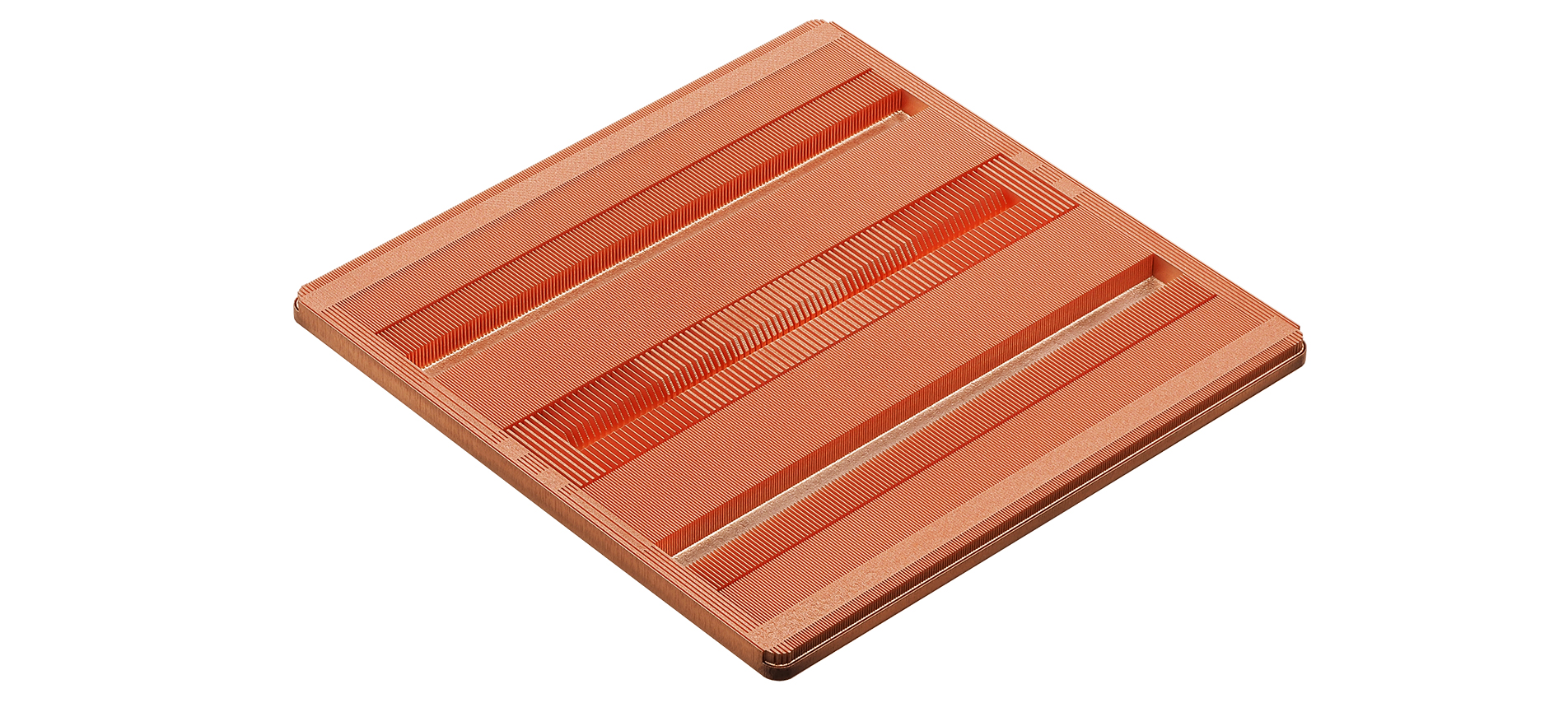

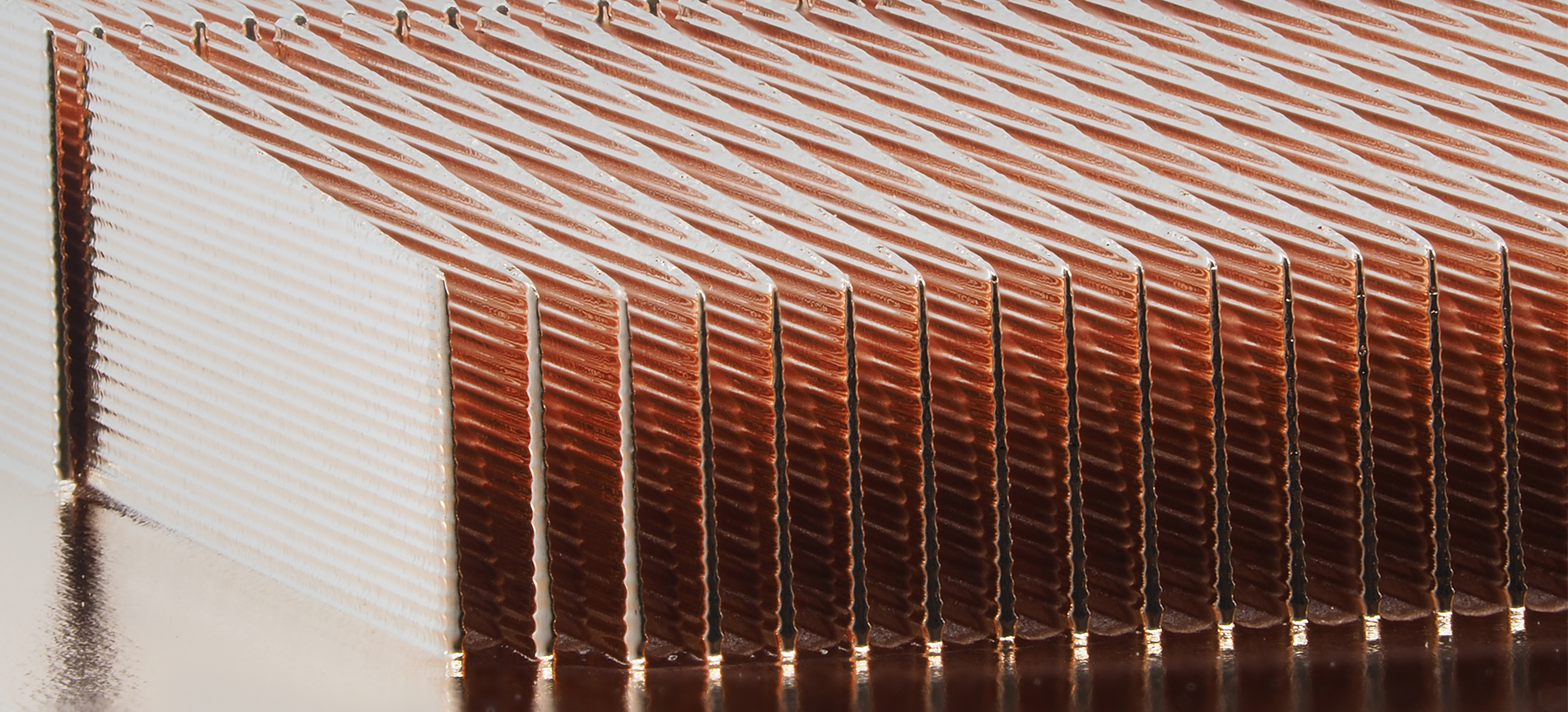

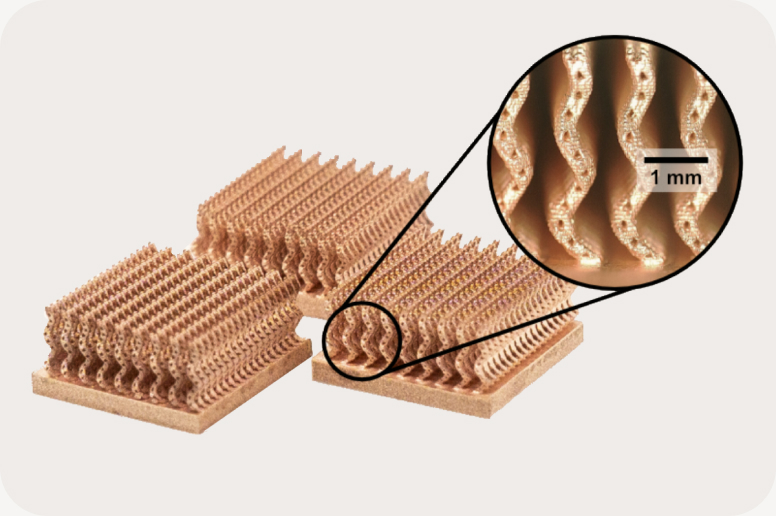

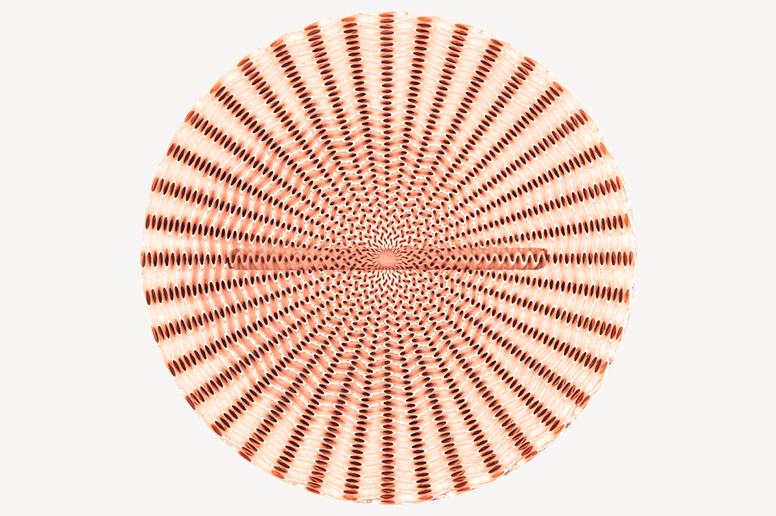

High-Resolution Metal 3D Printing at Scale

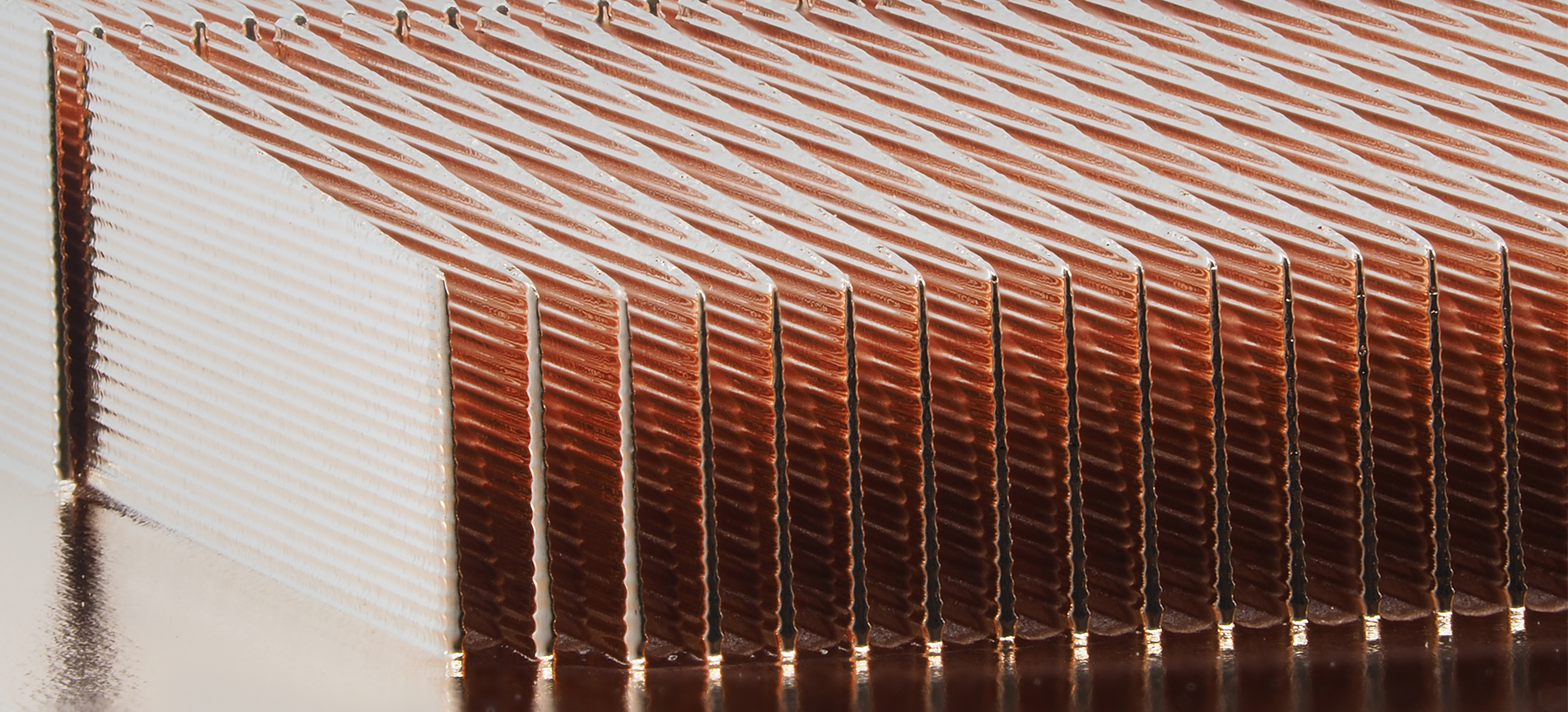

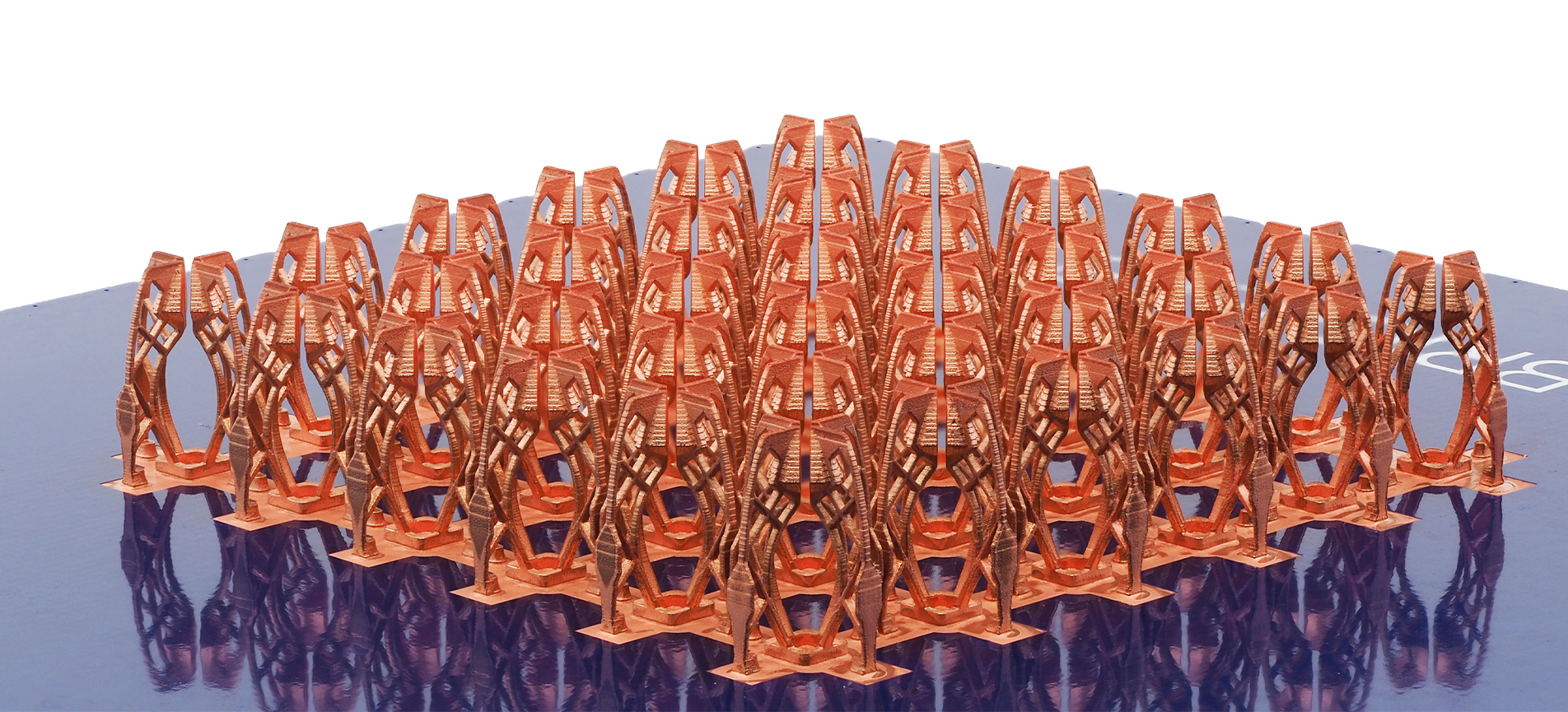

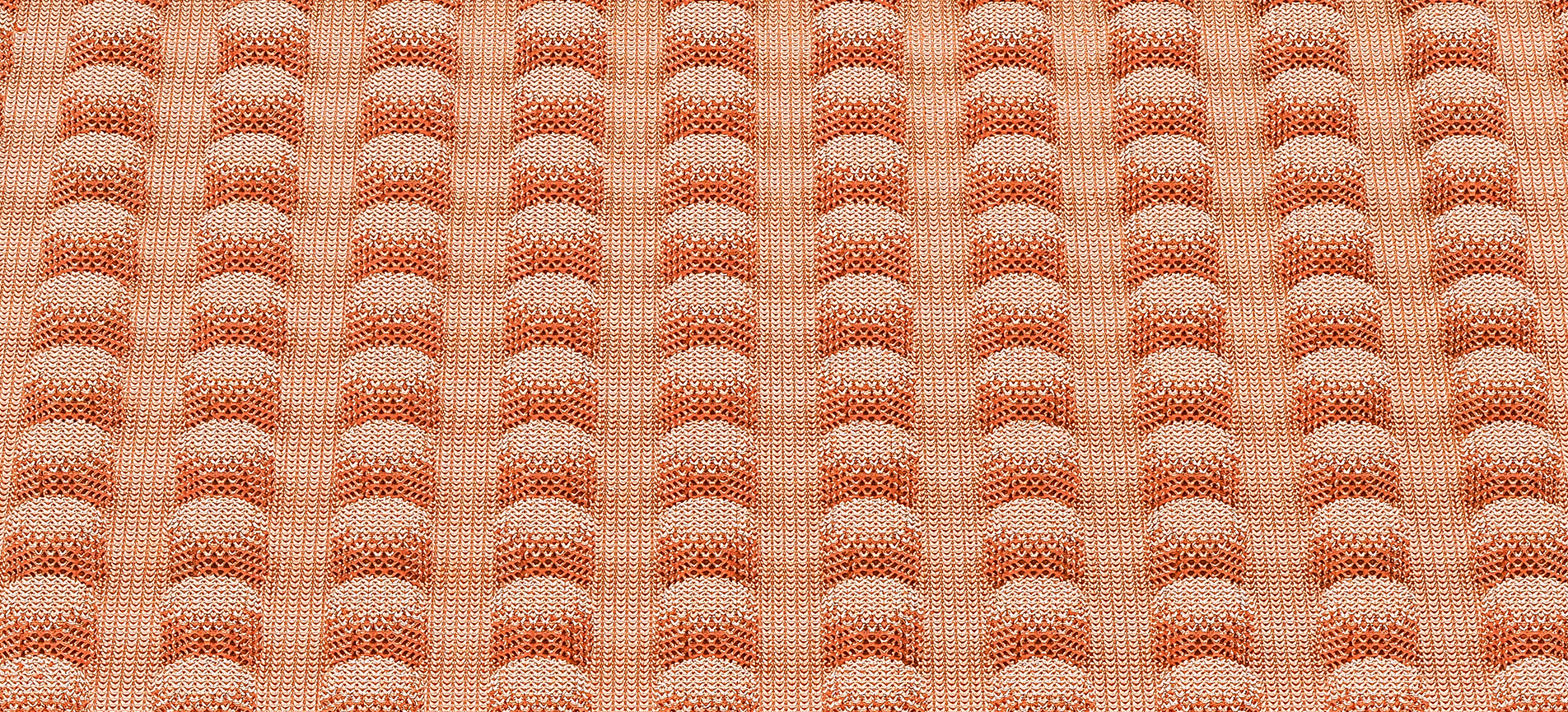

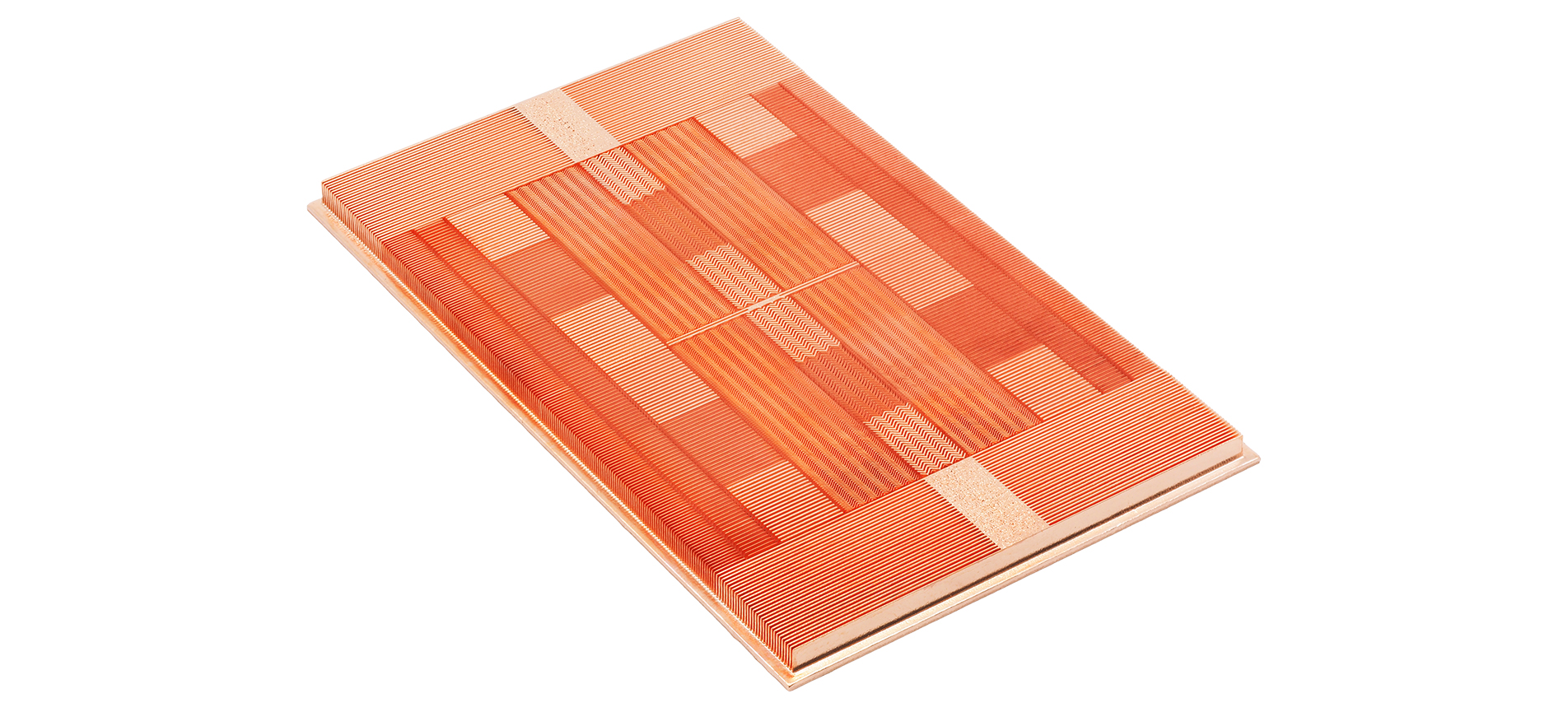

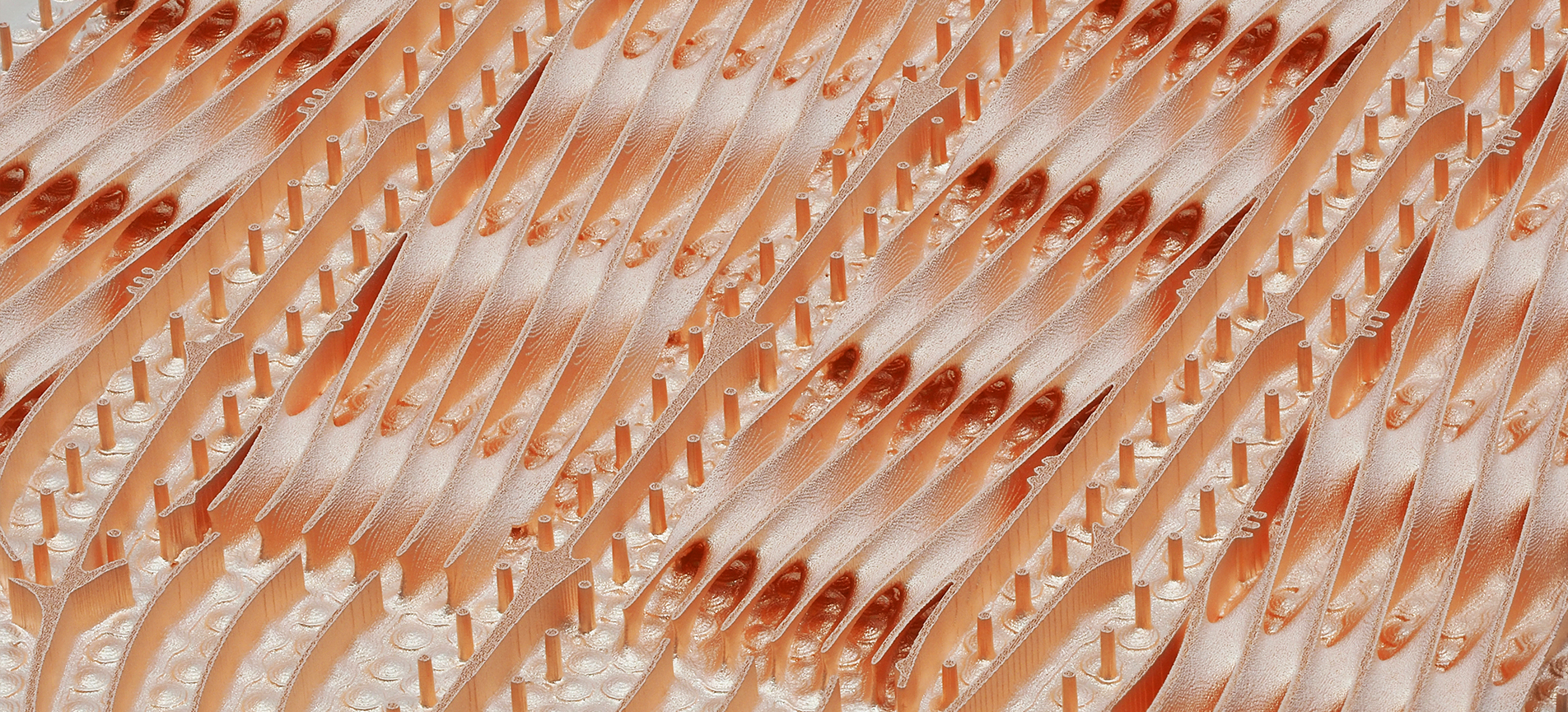

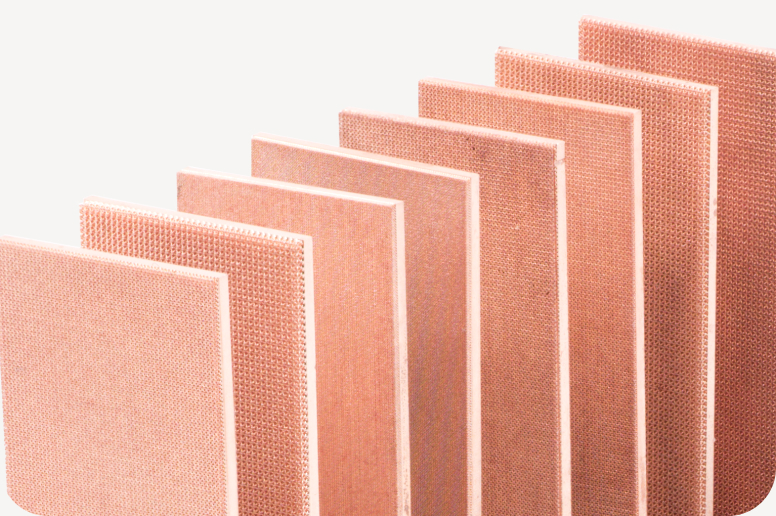

Electrochemical Additive Manufacturing (ECAM) is a room-temperature 3D metal printing technology that produces complex, dense metal parts without post-processing. This electrochemical approach allows for micron-scale feature resolution, complex internal features, high-purity materials, and rapid scalability to support mass manufacturing

HIGH PERFORMANCE

SCALABLE

SUSTAINABLE

HIGH PERFORMANCE

Ultra-high resolution, high purity components, with the capability to directly print onto temperature-sensitive substrates such as PCBs, silicon, or existing metal components

SCALABLE

Our patented microelectrode array printhead allows for the reliable production of high-quality parts, uniquely combining established technologies to manufacture at a mass scale.

SUSTAINABLE

ECAM enables a 90% reduction in greenhouse gas emissions relative to alternative additive technologies and traditional manufacturing.

Focused on Bringing Your

Product to Market

slide 5 to 7 of 3

PROVIDE

- De-risk and prove scalability to deliver product launch

- Establish high-volume and reliable supply

IDENTIFY

- Identify need and potential solutions to problem

- Create first prototypes of proposed solution

CREATE

- Optimize solution and validate compliance to technical requirements

- Demonstrate path to scale and implement

PROVIDE

- De-risk and prove scalability to deliver product launch

- Establish high-volume and reliable supply

IDENTIFY

- Identify need and potential solutions to problem

- Create first prototypes of proposed solution

CREATE

- Optimize solution and validate compliance to technical requirements

- Demonstrate path to scale and implement

PROVIDE

- De-risk and prove scalability to deliver product launch

- Establish high-volume and reliable supply

IDENTIFY

- Identify need and potential solutions to problem

- Create first prototypes of proposed solution

CREATE

- Optimize solution and validate compliance to technical requirements

- Demonstrate path to scale and implement

PROVIDE

- De-risk and prove scalability to deliver product launch

- Establish high-volume and reliable supply

IDENTIFY

- Identify need and potential solutions to problem

- Create first prototypes of proposed solution

Hyper Scalable

High-Impact Applications

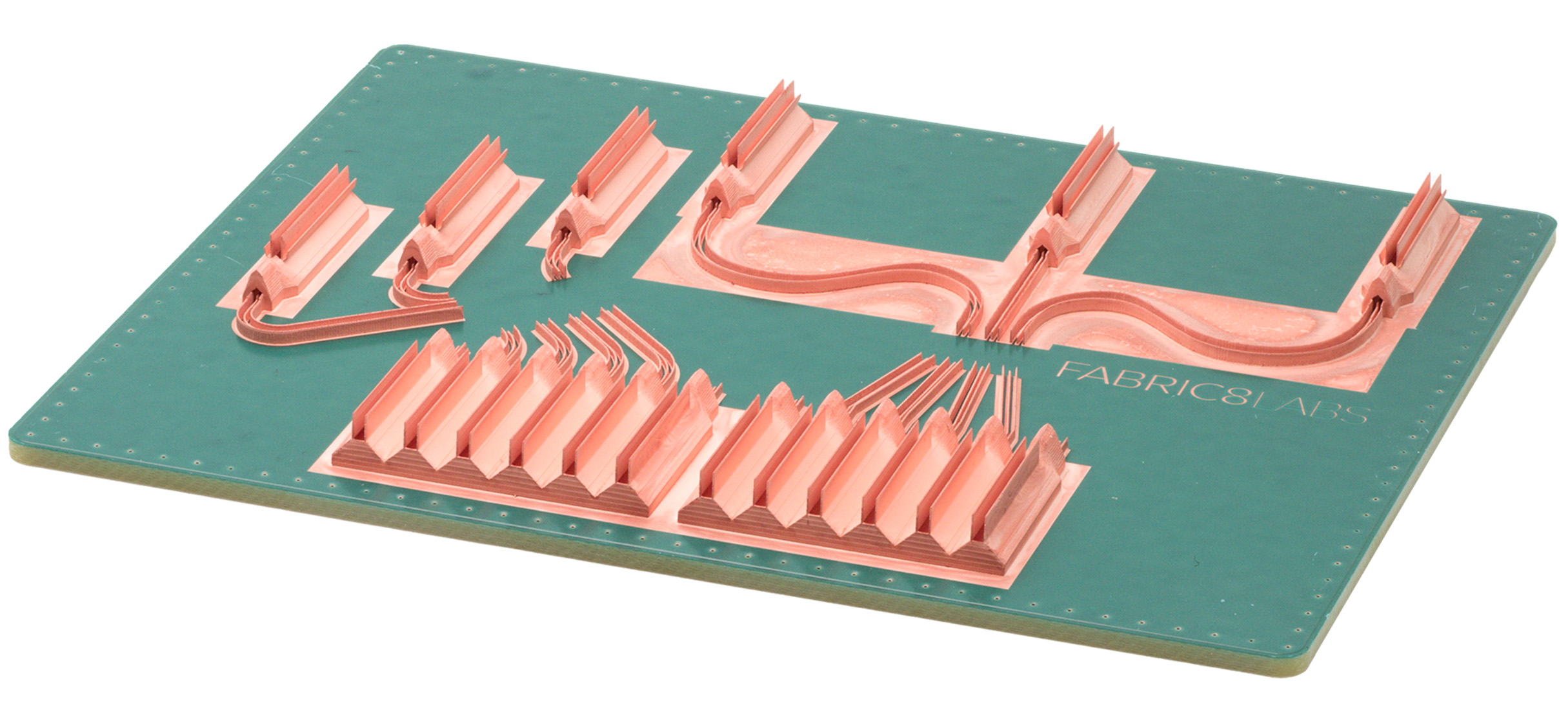

ECAM’s unique ability to deliver high-resolution, 3D printed metal components without post processing makes metal additive manufacturing accessible to a broad set of industries. ECAM is uniquely suited to deliver high-purity copper with exceptional thermal and electrical properties. High-performance products can be customized and mass-manufactured to address the most challenging technical problems - from cooling the latest high-power AI chips to high-frequency satellite communication systems and beyond.

PRESS

News

Fabric8Labs to Showcase Advanced ECAM Cold Plate Solutions with Wiwynn at OCP Global Summit 2025 Read more

News

Fabric8Labs’ ECAM Technology Selected by AEWIN for Advanced Thermal Management Solutions Read more

News

Fabric8Labs to Showcase ECAM Enabled Cold Plate with Wiwynn at Computex 2025 for Best-in-Class Liquid Cooled AI Data Centers Read more

Our Supporters

slide 5 to 8 of 12